| Sign In | Join Free | My carsrow.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My carsrow.com |

|

Brand Name : RUNNING

Model Number : XL-1000

Certification : CE,SGS

Place of Origin : China

MOQ : 1 set

Price : $2,500 ~ $4,000 /set

Payment Terms : T/T, L/C, Western Union, MoneyGram

Supply Ability : 50000sets/year

Delivery Time : 7 working days

Packaging Details : FCL/LCL

Application : conveyor belt edge repair

Material : High Strength Aluminum Alloy

Type : Repairing vulcanizer

Core Components : Pressure vessel, Pump

Heating Time : Less Than 25 Minutes

Curing Time Set Adjustable Range : 0-99 Minutes

After-Sales Service : Video Technical Support

Warranty : 2 Years

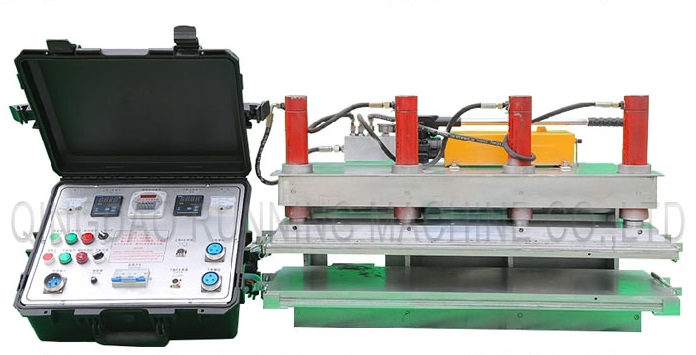

Rubber Conveyor Belt Edge-Repairs C-Clamp Repair Vulcanizing Machine

Machine specifications of Rubber conveyor belt edge repairing machine:

| Model

| XL-1000*300mm,XL-1200*300mm or customized |

| Voltage

| 220V/380V/400V or as customized |

| Pressure (Mpa)

| 1.0-2.0 Mpa |

| Dimension(L*W*H)

| 1250*550*500 mm |

| Weight

| 150 kg |

| Temperature range | 0-200℃ |

Special requirements: Voltage, Pressure, Temperature, Heating platen dimension etc. we can make special for you, if you have any requirements.

Application method

1. Fill glue inthe damaged areas that need to be repaired(see the adhesive part in the vulcanization process of the belt joints, or the demonstration by our staff when the equipment is being tested);

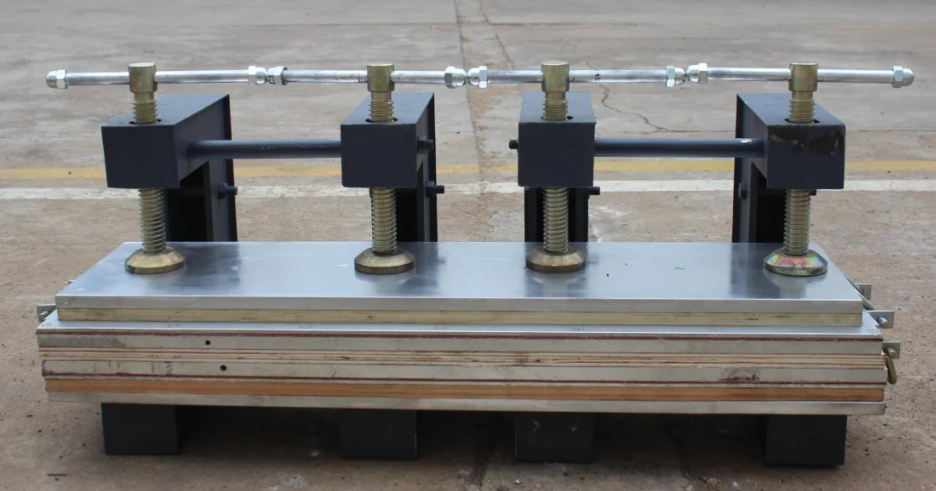

2. Put the bottom plate, water pressure plate and lower heating plate under the damaged areasof the belt according to the structural diagram.

3. Put the upper heating plate,Insulation board on the damaged areasof the belt.Align the top and bottom plates.

4. Lockedequidistantlythen tighten the bolts.

5. Get the first power wire well connected to electric control box. Connect the second wire with electric control box and the upper and down plates.Note that it corresponds to the signon the electric control box.

6. Connect the end of the high pressure pipe with inlet opening of water pressure plate. And connect another end of the high-pressure pipe with water output hole of water pump.Switch on, add pressure upon vulcanizing machine.

Features of Rubber conveyor belt edge repairing machine:

1.Rapid heating: from 20 ℃ to 145 ℃ only takes 20-25 minutes;

2.Uniform temperature: heating plate maximum temperature and minimum temperature difference does not exceed 3 ℃;

3. Rapid cooling: the heating plate from 145 ℃ to 65℃ cooling only takes 15-20 minutes;

4.Durable High-strength durable aluminum alloy allows maximum pressure 2.0 Mpa

Application method

1.Fill glue inthe damaged areas that need to be repaired(see the adhesive part in the vulcanization process of the belt joints, or the demonstration by our staff when the equipment is being tested);

2.Put the bottom plate, water pressure plate and lower heating plate under the damaged areasof the belt according to the structural diagram.

3.Put the upper heating plate,Insulation board on the damaged areasof the belt.Align the top and bottom plates.

4. Lockedequidistantlythen tighten the bolts.

5.Get the first power wire well connected to electric control box. Connect the second wire with electric control box and the upper and down plates.Note that it corresponds to the signon the electric control box.

6.Connect the end of the high pressure pipe with inlet opening of water pressure plate. And connect another end of the high-pressure pipe with water output hole of water pump.Switch on, add pressure upon vulcanizing machine.

Package of Rubber conveyor belt edge repairing machine:

The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tiger,we will use pe film for packing or pack it according to customers special request.

Our Services

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Customer Vistiting

Technical Parameters (Reference)

|

|

Edge Repairs C Clamp Conveyor Belt Repairing Machine Images |